s.A. SEMO GLASS MACHINES

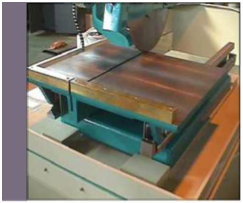

MANUAL SAWING MACHINE T40

-

•Cast iron upper assembly

-

•Grooved piece-holding work table, fitted on rollers

-

•Stainless steel guiding rails

-

•Stainless steel rail guards

-

•Protection hood with integrated water spraying

-

•Rigid and streamlined lower frame

-

•Cooling water recovery tray

-

•Sawing disk height adjustment system

-

•External control cabinet

-

•2 speeds electric motor Manufactured in compliance with all EC standards

STANDARD EQUIPMENT

OPTIONAL EQUIPMENT

TECHNICAL CHARACTERISTIC

The work table, which is grooved to offer enough space for the sawing disk, is made of cast iron, so that it is characterized by exceptional rigidity.The movement is made on rollers equipped with optimally dimensioned ball bearings.

The stainless steel guiding rails are protected against glass particles and water projections by sturdy protection guards, also made of stainless steel. The lateral access to the machine enables easy maintenance.

The profile of the guiding rails as well as the holding rollers allow a high degree of position accuracy and easy movements.

TheT40 is supplied with a stainless steel protection hood dimensioned for disks 0 400 and 500 mm. The function of this protection hood is protecting the operator against water projections and sharing out correctly the cooling liquid on both faces on the diamond disk. The hood may be easily removed for changing the sawing disk.The quantity of cooling liquid is adjustable. An optional stainless steel recovery tray allows the use of our additives SD17, SD18, SD19, which have been developed especially for the lubrication of our diamond abrasives.

-

•Streamlined upper frame

-

•Stainless steel water recirculation tray (capacity: 400 liters) with recirculating pump

-

•Electronic speed variator (speed range: 300 to 3000 rpm)

-

•Diamond tools

-

•Cutting/sawing accessories

-

•Cooling additive for the recirculation system

The stainless steel guiding rails are protected against glass particles and water projections by sturdy protection guards, also made of stainless steel. The lateral access to the machine enables easy maintenance.The profile of the guiding rails as well as the holding rollers allow a high degree of position accuracy and easy movements.

TheT40 is equipped with a sturdy and accurate spindle, adapted to diamond abrasive disks with a continuous or segmented rim (max. disk diameter: 500 mm). The machined disk adaptors perfectly hold and guide the tool.The spindle end warping is lower than 0.005 mm.

SEMO S.A. BOULEVARD PRINCE HENRI 3A - LU-1724 LUXEMBOURG

SALES : 00 32 64 26 58 91